Meet the Makers: Likamee Wool Rugs, Eco-Friendly and Imperfectly Perfect

In the age of mass-production and overconsumption, artisanal crafts seem to be making a comeback as more and more people crave authenticity over standardised manufacturing. We’re starting a new series to highlight the talented Croatian artisans creating extraordinary things, looking to learn more about their crafts. First up in Meet the Makers, an interview with the woman who’s turning discarded sheep fleece into stunning, eco-friendly wool rugs

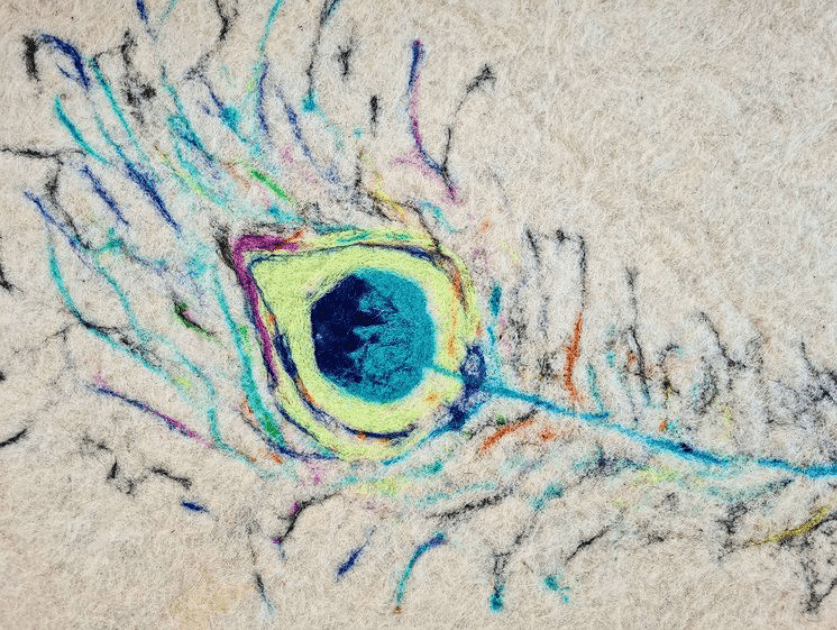

Scrolling through my news feed one day, an image caught my eye. A star-shaped white rug, covered in streaks of bright pink and orange, that looked incredibly soft and entirely unique. That’s how I first learned of Likamee wool, a small family business manufacturing felted wool rugs.

Likamee wool is run by two exceptional women: Nada Jandrić, the artisan creating the rugs, and her daughter Ivana who manages the Likamee socials and is also familiar with the craft herself. I reached out to them to learn more about their work and the stars aligned just right for us to meet in Zagreb for a chat.

Blurring the line between home decor and art, Likamee rugs are beautiful, one of a kind pieces, but there’s a lot to appreciate about this unique product beyond the aesthetic.

All the rugs are handmade, eco-friendly and animal-friendly, and I was curious to find out what led Nada to start practising such a specific craft. I thought this creative endeavour may have organically evolved from a love of arts and crafts in general, but she was in fact inspired by a documentary she saw about the environmental impact of wool as a pollutant.

You read that right - raw natural fiber can very well be a pollutant. Annual sheep shearing leaves behind massive quantities of fleece which essentially turns into waste overnight. Some people burn the leftover wool, some bury it, some just send it to landfill. On her part, Nada wanted to work out a way to recycle the fleece and give it a new life.

‘I had some unprocessed wool at home and the documentary got me thinking. If I could get more wool, what would I do with it? I don’t knit, I don’t spin yarn… I wanted to do something no one else was doing. So I did some googling, learned about felting, and I really liked the concept. I gave it a try; I started small, making pom-poms. Then I got myself a few felting needles and little by little, my projects expanded in size. Small at first, the rugs grew larger and larger until I made one with a 2-metre diameter.’

That particular rug is the largest she made to date and weighs an impressive 8 kilos, but on average Likamee rugs weigh around 2-3 kilos each (6,5lb). Coincidentally, that’s exactly how much wool is typically shorn from a single sheep, resulting in a neat principle of one sheep - one rug, give or take. I was delighted to learn that Likamee wool rugs have an easily traced origin, and a sweet story at that.

‘I source my wool from a woman who lives in Lika and tends to a flock of one hundred sheep. She loves those sheep so much. Each one has a name, and they respond to their names when called! It’s really something else. As an animal lover, I want that flock to be preserved for as long as possible.’

Lika Pramenka sheep / Wiki Commons

Animal-friendly manufacturing is a crucial part of the Likamee philosophy. Some of the rugs are made to imitate the look of sheepskin, but only in appearance: batches of shorn fleece are bonded by felting, resulting in beautiful and durable pieces created without any harm coming to animals.

‘My sheep are all safe and sound, they just get a haircut every once in a while’, said Nada with a laugh.

A sheep fleece Likamee rug with felted mat backing

These days, sourcing wool is the least of her concerns. Friends and family were very much on board ever since they first learned about the rugs, and everyone was happy to help by bringing more fleece for future projects. Nada soon had so much wool on her hands, storing it became a challenge. Once you have the raw material ready, what’s next?

As you might imagine, making a woollen rug by hand is a lengthy, demanding process. Nada and Ivana took me through all the steps involved in hand processing of wool, and learning how much time and effort is invested into each piece only made me appreciate the craft all the more.

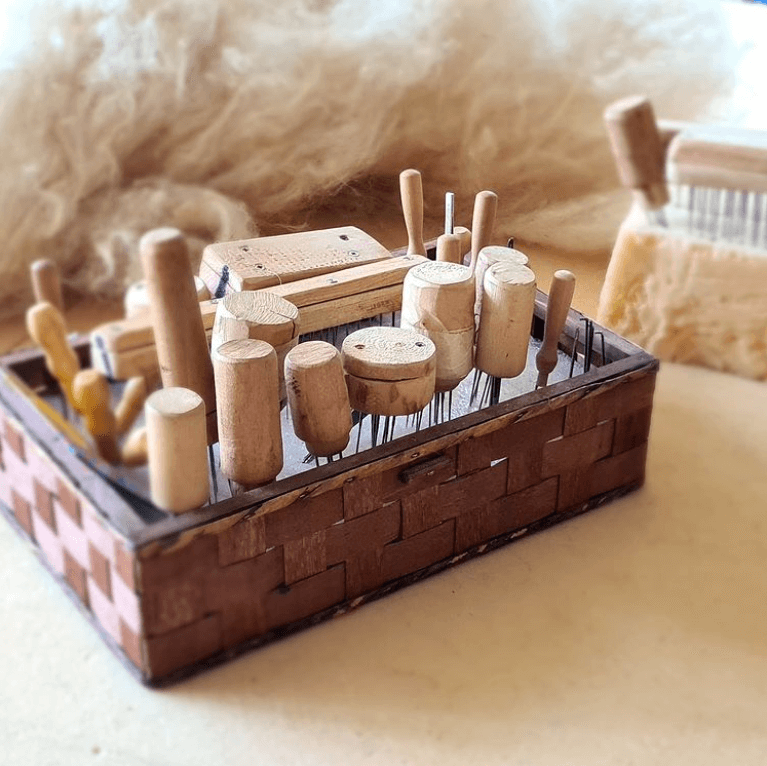

An assortment of felting needles, all handmade for Likamee manufacturing purposes

‘Say I was making a small rug and putting a few hours into it every day, it’d take me about a week to finish it. Since I’m basically stabbing wool [with the felting needle] by hand the whole time, I can work for four hours at a time, tops', says Nada. Check out the Instagram video showing the first stage of the dry felting process.

The creation of a rug is just the final step, though, and it’s the preparatory work that actually requires the most effort. There are stages to working with unprocessed fleece: it needs to be washed first, and that alone can take days.

Raw fleece typically has an unpleasant smell and is covered in mud, dirt and grease, so it needs to go through the wash a few times before it’s considered clean enough for further processing. Soak, rinse, repeat. Nada and Ivana do it all by hand.

‘You could technically use a washer, but all washing machines are too rough on wool even on the most gentle cycles. What occurs is that the fleece sort of felts itself and then you need to rip it apart again. That’d be incredibly hard: once wool is felted, it can very well last forever. So we wash it by hand instead.’

Once it’s air dried, the clean fleece goes through several rounds of combing. It’s split into smaller chunks with the help of a carding machine, is then combed by hand, and finally goes through a mechanical tool for fine carding (see the carder in action in this video). Is that the big contraption I saw on their Instagram? We wish it were big, they replied with a laugh.

The biggest carding tools intended for hobbyists are 30cm wide - it’s not much when you have to prep enough wool to make a rug, but anything bigger than that is only made for industrial manufacturing. They could really use a larger carder to process more wool at once, but had no luck searching for one.

‘Since my dad can make anything, he offered to build us a custom carding tool if we got him a metal sheet fitted with combing pins. Turns out, you can’t get one anywhere. We couldn’t source individual parts to build a bigger carder on our own, and so we struggle with the small one that we have. That’s why it takes so long; it’s a lengthy process in part due to the equipment’, explained Ivana.

Rough batches of wool are fine-combed until they transform into soft, airy clouds:

At that point, it’s finally time to felt. Several sheets of wool are stacked on a foam mat to make a rug, the number of sheets depending on the type of wool. Some are softer, some a bit rougher.

‘Our wool from Lika is more coarse, it takes more effort to work with. I also use wool from Pag island, that one’s softer. Interestingly, both are the Pramenka sheep breed, just originating from different areas.’

All Likamee rugs are unique, and Nada never makes the same design twice because it’s virtually impossible to repeat the same pattern. While some rugs retain the soft hues of natural sheep fleece, I’ve noticed a few eye-catching designs with accents of colour.

‘I started to dye the wool just to see how it would turn out. Since I’m working with eco wool, it only made sense to use eco-friendly dyes as well. I used coloured pencils at first and liked how it came out, then I started using natural purple dye. I’m planning to give avocado a try too… but mostly I just use natural wool. The experiments are more to ensure I have enough dyed wool at hand in case someone commissions a rug in a specific colour or pattern.’

Commissions are coming in indeed, and what started as a creative experiment and evolved into a hobby is now taking the shape of a business. For the last five years, it’s been all about learning. Now they’re working on branding and marketing, with Ivana managing the Likamee website and social media pages.

While they would both love for the project to become commercially viable and turn into a fully fledged family business, they primarily aim to build a strong design brand with a well-defined image: eco-friendly, high quality products.

In the meantime, they’re enjoying the creative process. Ivana said, ‘People love working with their hands, but aren’t fully aware of this until they actually start making something. It’s meditative, you get completely lost in it. It’s a different kind of focus than filling Excel sheets or preparing work presentations. We really enjoy it. It can be exhausting, but it’s so fulfilling.'

'The work is challenging, but so interesting', agreed Nada. 'There are times you get annoyed when something isn't turning out as you planned, but once you see your finished product, you know it’s all been worth it.'

We wish the best of luck to Likamee wool - head over to their website to browse the rug selection, and follow them on Instagram.

Unless otherwise noted, all images are courtesy of Likamee wool.

40 Environmentally Friendly Anchorages Set Up in Kornati National Park

November 17, 2021 - With the long-term objective of protecting the sea surface and preserving Posidonia, the Sunce Association through the SASPAS project has installed 40 environmentally friendly anchorages in four bays of the Kornati National Park using a technique that will not negatively impact the environment.

During July 2021, through a project by Interreg Italy - Croatia SASPAS within the Kornati National Park, a total of 40 environmentally friendly anchorages were set up in the bays: Kravljačica, Strižnja, Šipnate, and Tomasovac, reports HrTurizam.hr. In each of these bays, 10 anchorages have been set up for vessels up to 16 meters long, according to the Association for Nature, Environment and Sustainable Development Sunce.

According to the Association, there is a buoy at each anchor point, and all buoys were set up using the "Earth Anchor" system - methods of drilling through sand and sea sediment into the rock surface where the anchors were shot directly into the seabed. Given the nature of the setup, the impact on marine sediment is short-lived and negligible.

“During the installation, and later the exploitation of the anchorage, there is no contact with the vegetation cover, which is extremely important for the preservation of sea flowers and why this anchor system is more environmentally friendly compared to the installation of concrete blocks. Each anchorage consists of a circular sea area with an anchor bolt in the center, as well as an anchor buoy with a final mooring loop of anchor rope next to it. It is important to emphasize that this solution was chosen to ensure that the anchor chain does not touch the seabed even during the lowest water level. The anchor mooring works in such a way that the vessel is moored to the anchor rope and depending on the influence of the wind on the vessel, it rotates around the anchor buoy.'', states the Sunce Association.

The installation of 40 environmentally friendly anchorages is one of the goals of the SASPAS project, which included a campaign aimed at raising public awareness, especially boaters, about the importance of protection and preservation of sea flowers, with special emphasis on Posidonia.

Photo: Sunce Association

A special focus was on the preservation of Posidonia (Posidonia oceanica), a strictly protected species. Posedonia is a sea flower and endemic to the Mediterranean Sea, and it is the Posidonia meadows that are considered to be the most important ecosystem in the Mediterranean because they are oxygen factories and carbon dioxide stores. Marine organisms, primarily fish, seek shelter among their leaves, spawn and reproduce. Despite their prevalence, they are endangered by numerous human actions, and the biggest threat is precisely free anchoring.

With the successful installation of such an anchor system, as part of the SASPAS project, the long-term goal of the Kornati National Park is to establish anchorages in all 19 bays, as well as to completely ban free anchoring in the national park, has begun.

The Sunce Association was founded in 1998 by a group of Split intellectuals to respond to society's growing need for an independent and professional body to offer solutions to environmental and nature protection issues. Today, the Association is present at the national and international level as one of the leading organizations for nature and environmental protection in Croatia.

For more, make sure to check out our dedicated lifestyle section.

Initiative Signed for Green Passenger Catamarans

ZAGREB, 25 Oct 2021 - An initiative called "Autonomous electric vessels for smart islands and cities" was signed on Monday with the aim to build 21 green catamarans, watercraft with zero harmful emissions that rely solely on green fuels.

The initiative was launched and signed by Tomislav Uroda, director of the iCat company, Dubravko Majetić, dean of the Zagreb Faculty of Engineering and Shipbuilding, Gordan Gledec, dean of the Zagreb Faculty of Electrical Engineering and Computing, Boris Ćosić, director of the Technology Transfer Centre, and Nedjeljko Perić, director of the Nikola Tesla Innovation Centre.

The initiative envisages building 21 catamarans for 100 to 300 passengers in three sizes. One of each model will be deployed along the Adriatic as part of a pilot project to test the possibilities of seven destinations.

The development of the fleet will require the development of the energy infrastructure for the supply of electric vessels with electricity. The project, therefore, envisages developing charging stations with battery storage and solar power plants. The battery tanks, by connecting to the energy infrastructure, will contribute to the development of smart islands and cities as part of a system of smart grids facilitating the storage and supply of electricity.

The initiative also envisages developing a vessel steering and monitoring system based on progressive methods and artificial intelligence. Vessel monitoring and steering, a robotized system for filling the vessels' energy tanks, and a system of smart high-power charging stations which use energy from renewables represent the backbone of the development and application of modern technical solutions in maritime transport.

Croatian islands are rich in energy sources and can be leaders of the energy transition to a fully carbon-neutral economy by 2050, it was said.

For more made in Croatia news, follow TCN's dedicated page.

Kaufland Introduces Additional Measures to Reduce Plastic Waste

July 6th, 2021 - Kaufland continues to operate according to the Schwarz Group's REset Plastic strategy and has introduced a responsible fruit and vegetable bag, reusable lid, and set clear goals for reducing plastic in the environment.

24Sata reports, Kaufland is the first retail chain in Croatia to completely abolish disposable plastic bags at checkouts, and disposable plastic utensils, cutlery, plastic sticks, and straws were withdrawn from sale and replaced with alternative sustainable solutions such as paper, wood, and other products.

An additional engagement in the fight against plastics is the responsible bags in Kaufland's offer intended for fruits and vegetables. They are airy and suitable for storing fresh food and can be washed, which allows long-term use, and once the bag can no longer be used by disposing of it in plastic waste, and it can be 100% recycled. Kaufland wants to encourage its customers to, using the multiple variants, actively participate in reducing plastics in the environment. According to Kaufland's internal data, about 100 tons of plastic bags from the "very light plastic bags" category are used in one year in the fruit and vegetable department, so using multiple variants instead of very light disposable bags could reduce the amount of plastic in circulation.

In addition, a reusable lid for dairy products from brands K-Classic, K-take it veggie and K-bio has been introduced, but it can also be used on products from other brands. In order for the products to be hermetically sealed and stay fresh longer after opening, the offer includes a reusable lid that can be washed in the dishwasher, and with all the above, using this lid actively helps to reduce the amount of plastic in the environment.

As part of the international strategy for reducing plastic REset Plastic, Kaufland, as part of the Schwarz Group, has set two clear goals: by the end of 2025, it wants to use an average of 20% recyclable in its own packaging and 100% of these packaging should become maximally recyclable. By the end of this year, it will completely eliminate the use of black plastic to make it easier to recycle plastic packaging, thus enabling a circular recycling process.

"We approach the topic of environmental protection very responsibly, and through various activities, we try to raise awareness about environmental protection among our customers as well. By using reusable bags and lids, each individual does something good for our planet and creates a better future for all of us," said Marija Franić, Head of Corporate Communications at Kaufland.

For more, follow our lifestyle section.

Croatia Longboards Offer Cool and Green Around-Town Travel

ZAGREB November 19, 2020 - Noticeably bigger than a skateboard, longboards are a cool alternative to urban travel. Meet Croatia's first longboard manufacturers, Crushboards, whose eco-friendly products are healthier to use and way more stylish than other green options

You can walk around some European towns and cities and wonder just where the future is going to fit in. The narrow streets seem to want to accommodate only cars, with pedestrians demoted to the narrow edges. Zagreb isn't like that. Osijek and other towns and cities in Croatia are not like that. With 220 kilometres of dedicated cycle paths, the city of Zagreb and its residents have been quick to adopt the latest green-friendly ways of getting around the urban environment

With 220 kilometres of dedicated cycle paths, the city of Zagreb and its residents have been quick to adopt the latest green-friendly ways of getting around the urban environment

You only need take a glance at the generous cycle paths around Zagreb to see that this is a city that could easily take on the challenges of a future not reliant on fossil fuels – electric scooters, foldaway bikes, gyroscooters, electric skateboards and monowheels have joined bicycles on the streets of Zagreb as an easy means to get round the city. Could longboards be the next popular choice?

Started by three lifelong friends from Čakovec, Crushboards is the first company in the country to make Croatian longboards. Like a skateboard, only bigger, longboards are well suited to the urban environment of a city like Zagreb. Čakovčani (l-r) Marko Hlebar, Davor Nikolic and Sanda Bogdan inside the Zagreb workshop of Crushboards © Vedran Pažin

Čakovčani (l-r) Marko Hlebar, Davor Nikolic and Sanda Bogdan inside the Zagreb workshop of Crushboards © Vedran Pažin

“This board is longer than a skateboard - 100 centimetres in length.,” Crushboards co-founder Marko Hlebar told TCN when we went to visit their workshop in Zagreb. He runs Crushboards with Davor Nikolic and Sanda Bogdan. “It's a bit heavier than a normal skateboard and uses different wheels. You can perform different tricks on each, dependant on the weight of the board, but the main thing for us is that a longboard is easier to ride on in the urban environment, in the city.” Practising on a Crushboards longboard inside a Zagreb park. The boards are intended as much for a regular inner-city commute as they are for such trickery

Practising on a Crushboards longboard inside a Zagreb park. The boards are intended as much for a regular inner-city commute as they are for such trickery

“The wheels are larger so it's easier to travel on one of these in the city than it is on a regular skateboard,” Marko tells us. “It's better for travelling to work or to appointments, your feet get less tired.”

Rather than being the latest cool evolution in skateboards, it turns out that longboards have been around for a long time. In fact, the very first skateboards that were made probably looked more like the hip, eco-friendly product made by Crushboards than a regular skateboard. Crushboards see their main product as part of a lifestyle choice - so, it's little surprise to learn they also make their own super-cool t-shirts and accessories

Crushboards see their main product as part of a lifestyle choice - so, it's little surprise to learn they also make their own super-cool t-shirts and accessories

Skateboards were first made in America during the 1940s as a practice board for surfers who were prevented from taking to the waves because of bad weather. But, during its infancy, there were few options available to manufacturers in the skateboarding industry – boards were made using rollerskate wheels, whose size demanded a board closer to that of today's longboard.

The longboard was, therefore, the first popular urban skateboard and remained so until the 1960s. It has fallen in and out of fashion ever since – the development of ultra-fast wheels saw them rise again in popularity due to them being well suited to downhill racing (the bigger board better absorbs the vibrations produced from speed). The relatively recent phenomenon of longboard dancing has also increased the boards' popularity in Asia.

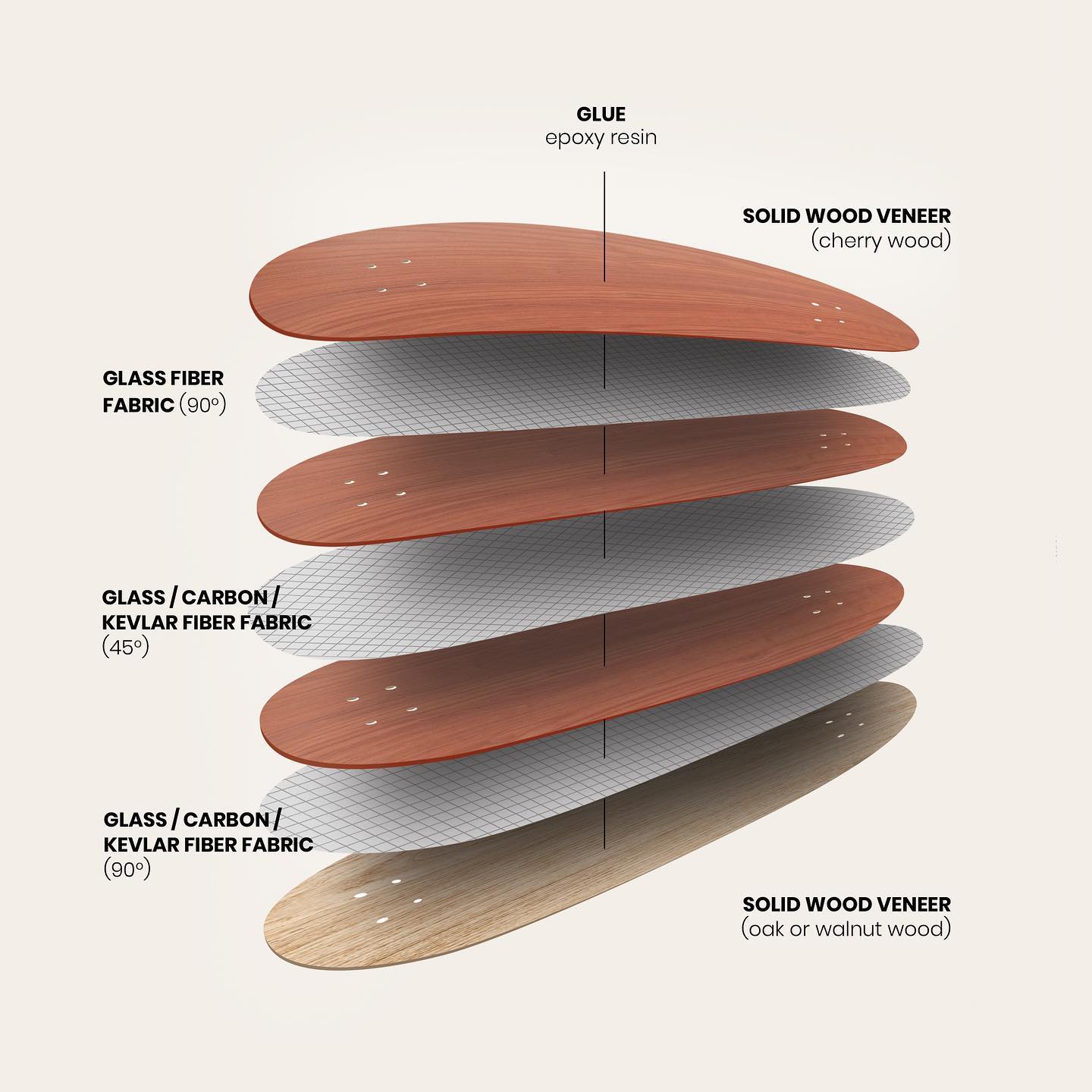

Like regular skateboards, several different types and designs of longboard exist for different uses. The ones currently made by Crushboards are specifically designed for urban travel. Their boards are made using several thin layers of different materials, which strengthen and provide flexibility when glued together. They are finished on the top side with either oak or walnut, with the other layers holding cherry, teak, fibreglass, carbon, kevlar and two veneers. The wheels and their mounts are currently imported, but Crushboards hope to eventually source as much of the materials required from sustainable sources within Croatia. Inside one of Crushboards' longboards

Inside one of Crushboards' longboards

With 220 kilometres of cycle paths occurring throughout Zagreb, the Croatian capital is quick to embrace green modes of transport. Many Croatians are also health-conscious – a motorised scooter or skateboard might get around the city quickly, but they don't increase your exercise quota. Perhaps there's room on Zagreb's streets for these cool urban alternatives to the skateboards of our youths?

All uncredited photos © Crushboards

"A Product with a Mission" by Violeta Hits Croatian Shelves

February 15, 2020 - Violeta, a Bosnian brand of toilet paper and similar products, announced that they'll offer to their Croatian consumers the same product they already know in very innovative packaging.

In Croatia, and you're absolutely forgiven if you don't know this unimportant factoid, most of the TP used is imported. I thought that nobody produced it, as when there was a lot of joking around at the Narodne Novine expense (the Official Gazette of Croatia company who tried and failed miserably at producing and distributing it, losing almost 10 million taxpayers' euros in the process) it was said that it would become the only toilet paper made in Croatia. Now a brief Google search introduced me to the Ola'la brand of the toilet paper and similar products, which I've never personally seen in stores, but apparently they exist.

In the absence of Croatian products, we buy imported, be it the traditional Slovenian stuff from Paloma, some international global producers, or in recent years increasingly, an import from Bosnia and Herzegovina: Violeta brand. The company is headquartered in Grude, owned by Petar Ćorluka, employs more than 900 workers and produces more than 200 hygienic products. It is one of the biggest companies in Bosnia and Herzegovina, and one of the biggest exporters. They're very present on the Croatian market, and recently they've announced the innovative packaging for their product (their announcement specifically mentions Croatia, although I personally don't understand why they wouldn't put it on other markets too).

It's still going to be their toilet paper. However, the packaging of the paper will be such to facilitate the use of the plastic bag as a - trash bag. I mean, we all did it at least once, it's quite a large bag, no reason why you shouldn't use it to put some garbage in there - except, there is a reason, and that reason is that once the TP bag is opened, there's no way to close it again to prevent from the garbage falling out. Now Violeta has solved that: their new packaging will include a tie, which will allow the users to simply tie the bag once it's full of garbage!

It's not a major change, neither for the company nor for the environment. However, in order to reduce waste we need to work together, the companies that produce products and the consumers. If the companies don't think about this problem, then the consumers can't show they care and buy products which reduce waste. And if such products exist, the consumers can buy them and entice other companies to consider reducing the amount of packaging.

The idea of the project 'Dual purpose for a higher purpose' was by a Croatian marketing agency Saatchi&Saachi. They've also decided to use the packaging itself as a key communication channel, instead of the usual communication campaign.

And with the current problems with recycling in Zagreb, the Violeta company probably couldn't have chosen a better time for this product!

Popular Vukovar Waterbus "Bajadera" Goes Solar this Year!

The popular Vukovar waterbus “Bajadera” by Danubium Tours has quickly become a recognizable tourist product of Vukovar and Croatia.

Sustainable Hotels in Croatia: Aminess Hotels & Campsites

Continuing our look at the sustainable hotels in Croatia, today we bring you Aminess Hotels & Campsites, located throughout Istria and Dalmatia.