Exotic Zagorje Banana Plantation Expanding to Serbia, Ivory Coast...

January the 4th, 2022 - Did you know that a Zagorje banana plantation exists on the very borders of the much loved Medvednica Nature Park? Head to Donja Stubica if you don't believe us.

As Poslovni Dnevnik writes, the owner of the Zagorje banana plantation rejected all of the typical and traditional local culture and started growing bananas and other unusually exotic fruits on the rolling green hills of Zagorje. Western Europe is his market, and he's expanding production down to Dalmatia, neighbouring Serbia, Albania, and all the way to the distant Ivory Coast. Meet Ivan Sulog, a most unusual Croatian farmer.

At the very border of the Medvednica Nature Park, where Donja Stubica borders Gornja Podgora, Mr. Ivan Sulog planted the very impressive Zagorje banana plantation.

''These are Indian bananas which are older than even the dinosaurs, they survived the ice age,'' explained Ivan for HRT.

''Indian bananas got that name because they were primarily eaten by the Indians, and banana because they taste just like eating banana cream. And that's how the Indian banana got its name. Unlike the chokeberry which you typically buy once and never again because they're too bitter and strong, this is something you try once and want more,'' Ivan explained.

''I heard a story about a lunatic planting bananas, and later I found out that I work for that lunatic!'' said Ivan's employee Mirjana Djurin. The Zagorje banana plantation doesn't just boast the famous curved yellow fruit, but also passion fruit, chili, Surinamese cherries, Indian bananas, juzu, kumquat, and so on. Quite obscure indeed for continental Croatia.

''People hear what I do, and it sounds so beautiful and exotic to them, they expect that my yield is always good and that I'm raking in the cash, which isn't really the case,'' Ivan explained.

''These are the first urban orchards, probably the first in all of Europe, there are urban gardens in Zagreb, where people come and take 20 square metres, and someone maintains it for them or they maintain it themselves. We've got more or less then same model here, if you don't have land, you can't plant your bananas. From now on, people can rent five bananas from us, put your name on them and all of the other information you want, and we take care of them until the harvest,'' said Ivan.

Now the unusual Zagorje banana plantation has even spread its wings and outgrown the borders of Croatia, starting up business in neighbouring Serbia, Indian bananas have been planted down in in Montenegro, and Albania is next on the cards, the Ivory Coast, too.

For more, check out Made in Croatia.

Increasingly Popular Croatian Sparkling Wines Most Sought After in Germany

December the 31st, 2021 - Croatian wines are extremely popular throughout the world and that isn't really news, but what about Croatian sparkling wines? It seems that the Germans have a real taste for it, with a lot of it being exported there.

As Poslovni Dnevnik/Marta Duic writes, according to the Croatian Chamber of Commerce (HGK), in the first nine months of this year, Croatian winemakers exported 403 hectolitres of sparkling wines worth as much as 870,000 euros.

The main markets for the wine were Germany, where 122 hectolitres worth 471,017 euros went, followed by the Netherlands, then neighbouring Bosnia and Herzegovina and Slovenia. One year earlier, when assessing the first nine months, exports were slightly higher, totalling 457 hl worth a massive 1,173,292 euros.

Growing demand...

The Belje winery is aware that Croatian sparkling wines are an important export asset, and just this week this winery launched a top-quality sparkling white wine - La Belle Grand. As they say from there, their new sparkling wine is a brut style wine, which is one of the most sought after in the world, and is characterised by "beautiful pearls" of many small bubbles.

“This summer, we installed a new line and equipment for bottling Croatian sparkling wines in our winery in an extremely short period of time, in order to expand our range and meet the growing market demands for this category of wine. La Belle Grand is our first sparkling wine prepared just for this year's festive period. With it, we're celebrating the end of the year in which we won 52 medals,'' points out Marijan Knezevic, head of winemaking development at Vina Belje. Another new brand on the market is the Slavonian Enosophia from Fericani.

“In the first year of Enosophia's existence, we achieved some really nice results. Although we've only been present on the market since July, we've distributed almost 16,000 bottles of sparkling wine. For next year, we plan to produce and distribute a total of 77,000 bottles of sparkling wine, Nice to see you, Today Blance and Today rose. Enosophia is a brand that is focused on combining innovative technologies and traditions in the development of new flavours. We create light and modern Croatian sparkling wines, produced by the Charmat method and by following the demands of the market,'' explained Martin Kovacevic, chief oenologist of the Enosophia winery. Their Nice to see you sparkling wine is a combination of Chardonnay and Pinot Noir, and Today blanc is made from the much loved and very well known Croatian Grasevina variety.

"We're currently present in 50 outlets, meaning in restaurants and other catering and hospitality facilities. In the first year, our focus was primarily on presenting the brand here on the Croatian market, but despite that, we've already achieved positive results in terms of exports. Enosophia has been launched on the Japanese market with the sparkling wine called Nice to see you and we expect this trend to continue in the future. Our Croatian sparkling wines under the Feravino brand have also found their fans across many European countries, such as Belgium, the Netherlands, Switzerland and the countries of the more immediate region,'' added Kovacevic.

As he explained, their Today blanc sparkling wine is primarily intended for retail sale, while in the HoReCa channel it is marketed as a ''welcome wine'' or as a wine for the preparation of cocktails. Nice too see you is also available through the HoReCa channel, but can also be purchased through the Enosophia brand website. "As for our plans for 2022, we plan to present the second Today - Today rose, which will be produced from the Frankovka variety, which is the most represented in our vineyards," revealed Kovacevic.

The Pavlomir wine house from Novi Vinodolski also has a few export trump cards under its belt, producing four Croatian sparkling wines in the top category, an impressive 15,000 bottles a year.

For more, check out Made in Croatia.

Croatian Brist Olive: Vodnjan Family Business Sees Oil Shipped to USA

December the 31st, 2021 - The Croatian Brist Olive oils, made by a family business located in Vodnjan in Istria, have made their way across the pond to the United States of America, placing Croatian products firmly on the radar there once again.

As Poslovni Dnevnik/Marta Duic writes, one family business from Vodnjan is busy diversifying all of its activities, but the basis of everything they engage in is authentic products which are then exported to a number of countries across the globe. On the eve of the festive period at Br00m44 on Zagreb's famous Dolac market, a presentation of extra virgin olive oils of the new vintage Brist Olive brand from Vodnjan was held.

Lena Puhar O’Grady, who leads the presentations, education and marketing on Brist’s team, presented her family business, told the story of their brand development and guided guests through three of the six types of Brist Olive oil they currently produce. One monosort was tasted - Vodnjanska Buza oil, as well as two blends.

“Our olive grove is located in the vicinity of Vodnjan, it's beautifully positioned, overlooking the Brijuni islands and spreads over nine hectares where 2,500 olive trees grow, mostly indigenous Istrian varieties. We produce about 8,000 litres of oil per year, with the expectation of growth when all of the olives grow well and come to fruition,'' said Puhar O’Grady.

Demand is growing...

Each of their Brist Olive oils was then paired with a type of cheese from the Istrian Mljekara Latus from Zminj, with sourdough foccaccia from the Zagreb bakery Breadclub, and the tasting was then rounded off with a chocolate tart with olive oil, designed especially for the occasion by food blogger Janja Benic. The chocolate tart was served with a few drops of Brist’s Exclusive Selection olive oil, and as Puhar O’Grady explained, this is a form of olive oil made in a limited edition from selected olives from century-old buza and rozinjola trees.

As she claimed, the Brist Olive oil team process their olives in the Grubic oil mill in nearby Bale, with which they have a long-term cooperation, and their main customers are individuals, mostly foreign citizens paying visits to Istria. They realise their biggest sales directly in their store in the old town of Vodnjan and through online sales.

"Since the beginning of the coronavirus pandemic, our online sales have quadrupled since before. A large part of our clients come after participating in our guided tours and tastings in the olive grove,'' she said.

In addition, Brist Olive oil is exported through 20 international partners within the EU, Norway and Switzerland, and from this year for the very first time to America. They also cooperate with specialised stores, mainly in Istria and Zagreb, as well as restaurants throughout Croatia and the Milenij Hotel chain in Opatija.

For more, check out Made in Croatia.

Popular Lika Skripavac Cheese Expanding Sales Network and Offer

December the 28th, 2021 - The very popular Lika Skripavac cheese is set to expand not only its offer but also it's sales network following special recognition given to it by the European Union (EU) in the form of a much-sought-after label.

As Poslovni Dnevnik/Marta Duic writes, the much loved Lika Skripavac cheese has been awarded the European Union's label of protected geographical indication, the European Commission (EC) published in the Official Journal of the European Union on Tuesday.

As stated, the method of production of this special Croatian cheese, which became the 32nd Croatian product to boast EU protection, has been passed down from generation to generation and preserved to this day, and its crunchy properties, after which it got its name, occurs due to high fat and protein in the milk resulting from a specific diet the cows eat.

From the heart of Lika all the way down to Dubrovnik...

Native Lika products, including the Lika Skripavac cheese, are the basis of Vedrine's cheese business, which offers quite the variety of produce from Croatia's green heart.

This small family cheese factory is run by two married couples in the village of Brezik below Vaganski vrh on Velebit, and their plant processes about 180,000 kilograms of milk annually, and has more than 20 products in its range.

They recently opened a store in the town of Samobor, and at the beginning of next year they will open their seventh point of sale, in the Crnomerec district of Zagreb. In Samobor, consumers were introduced to some of the novelties Vedrine has on offer - small fruit yogurts, boiled cheese with garlic and butter in four variants, natural and salty, and butters with garlic and chives, which are set to reach the market in the spring.

In addition to their points of sale at markets in Zagreb and Zadar, this cheese factory also cooperates with specialised stores in Zagreb, Sibenik, Split and Dubrovnik.

"Before the coronavirus pandemic struck, we sold our products at the Samobor market, Samobor is an interesting market and people here really like domestic production. We haven’t hired anyone new, I do all of the work, but with the new location we’re opening we’ve hired one person. We have established cooperation with the Better Tomorrow Association of Persons with Disabilities by selling their pasta, as well, and we're looking for more small producers to work with,'' said Ana Todoric from Vedrine.

For more, check out Made in Croatia.

Meet the Makers: Likamee Wool Rugs, Eco-Friendly and Imperfectly Perfect

In the age of mass-production and overconsumption, artisanal crafts seem to be making a comeback as more and more people crave authenticity over standardised manufacturing. We’re starting a new series to highlight the talented Croatian artisans creating extraordinary things, looking to learn more about their crafts. First up in Meet the Makers, an interview with the woman who’s turning discarded sheep fleece into stunning, eco-friendly wool rugs

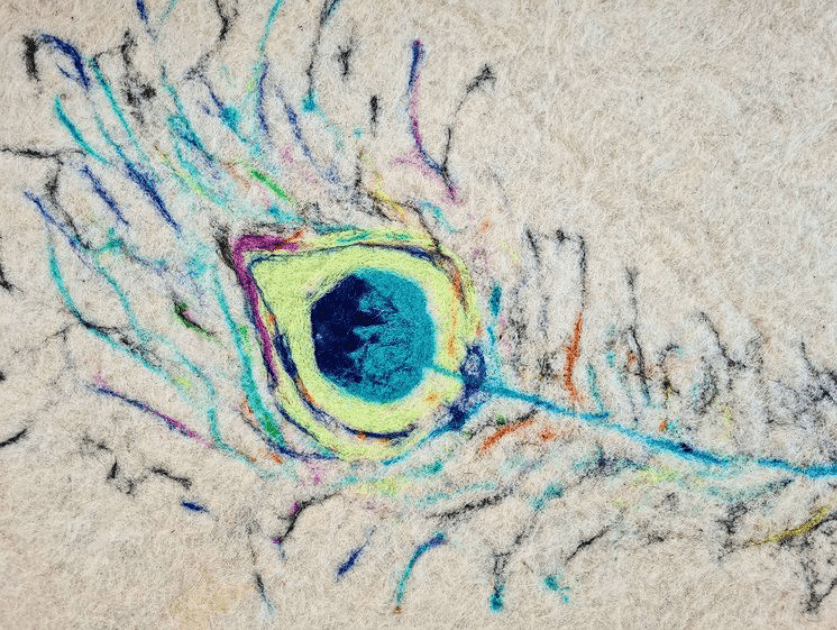

Scrolling through my news feed one day, an image caught my eye. A star-shaped white rug, covered in streaks of bright pink and orange, that looked incredibly soft and entirely unique. That’s how I first learned of Likamee wool, a small family business manufacturing felted wool rugs.

Likamee wool is run by two exceptional women: Nada Jandrić, the artisan creating the rugs, and her daughter Ivana who manages the Likamee socials and is also familiar with the craft herself. I reached out to them to learn more about their work and the stars aligned just right for us to meet in Zagreb for a chat.

Blurring the line between home decor and art, Likamee rugs are beautiful, one of a kind pieces, but there’s a lot to appreciate about this unique product beyond the aesthetic.

All the rugs are handmade, eco-friendly and animal-friendly, and I was curious to find out what led Nada to start practising such a specific craft. I thought this creative endeavour may have organically evolved from a love of arts and crafts in general, but she was in fact inspired by a documentary she saw about the environmental impact of wool as a pollutant.

You read that right - raw natural fiber can very well be a pollutant. Annual sheep shearing leaves behind massive quantities of fleece which essentially turns into waste overnight. Some people burn the leftover wool, some bury it, some just send it to landfill. On her part, Nada wanted to work out a way to recycle the fleece and give it a new life.

‘I had some unprocessed wool at home and the documentary got me thinking. If I could get more wool, what would I do with it? I don’t knit, I don’t spin yarn… I wanted to do something no one else was doing. So I did some googling, learned about felting, and I really liked the concept. I gave it a try; I started small, making pom-poms. Then I got myself a few felting needles and little by little, my projects expanded in size. Small at first, the rugs grew larger and larger until I made one with a 2-metre diameter.’

That particular rug is the largest she made to date and weighs an impressive 8 kilos, but on average Likamee rugs weigh around 2-3 kilos each (6,5lb). Coincidentally, that’s exactly how much wool is typically shorn from a single sheep, resulting in a neat principle of one sheep - one rug, give or take. I was delighted to learn that Likamee wool rugs have an easily traced origin, and a sweet story at that.

‘I source my wool from a woman who lives in Lika and tends to a flock of one hundred sheep. She loves those sheep so much. Each one has a name, and they respond to their names when called! It’s really something else. As an animal lover, I want that flock to be preserved for as long as possible.’

Lika Pramenka sheep / Wiki Commons

Animal-friendly manufacturing is a crucial part of the Likamee philosophy. Some of the rugs are made to imitate the look of sheepskin, but only in appearance: batches of shorn fleece are bonded by felting, resulting in beautiful and durable pieces created without any harm coming to animals.

‘My sheep are all safe and sound, they just get a haircut every once in a while’, said Nada with a laugh.

A sheep fleece Likamee rug with felted mat backing

These days, sourcing wool is the least of her concerns. Friends and family were very much on board ever since they first learned about the rugs, and everyone was happy to help by bringing more fleece for future projects. Nada soon had so much wool on her hands, storing it became a challenge. Once you have the raw material ready, what’s next?

As you might imagine, making a woollen rug by hand is a lengthy, demanding process. Nada and Ivana took me through all the steps involved in hand processing of wool, and learning how much time and effort is invested into each piece only made me appreciate the craft all the more.

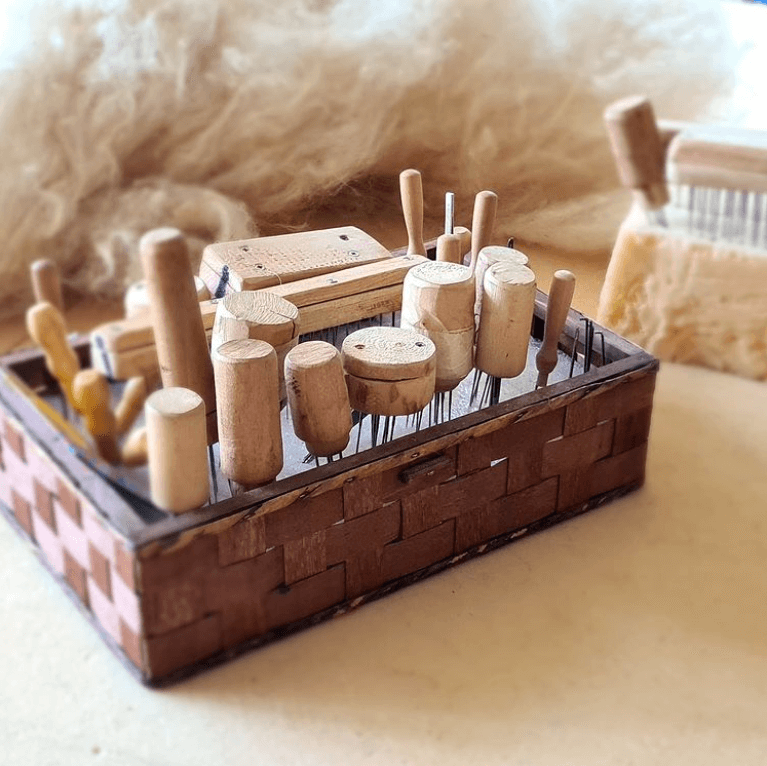

An assortment of felting needles, all handmade for Likamee manufacturing purposes

‘Say I was making a small rug and putting a few hours into it every day, it’d take me about a week to finish it. Since I’m basically stabbing wool [with the felting needle] by hand the whole time, I can work for four hours at a time, tops', says Nada. Check out the Instagram video showing the first stage of the dry felting process.

The creation of a rug is just the final step, though, and it’s the preparatory work that actually requires the most effort. There are stages to working with unprocessed fleece: it needs to be washed first, and that alone can take days.

Raw fleece typically has an unpleasant smell and is covered in mud, dirt and grease, so it needs to go through the wash a few times before it’s considered clean enough for further processing. Soak, rinse, repeat. Nada and Ivana do it all by hand.

‘You could technically use a washer, but all washing machines are too rough on wool even on the most gentle cycles. What occurs is that the fleece sort of felts itself and then you need to rip it apart again. That’d be incredibly hard: once wool is felted, it can very well last forever. So we wash it by hand instead.’

Once it’s air dried, the clean fleece goes through several rounds of combing. It’s split into smaller chunks with the help of a carding machine, is then combed by hand, and finally goes through a mechanical tool for fine carding (see the carder in action in this video). Is that the big contraption I saw on their Instagram? We wish it were big, they replied with a laugh.

The biggest carding tools intended for hobbyists are 30cm wide - it’s not much when you have to prep enough wool to make a rug, but anything bigger than that is only made for industrial manufacturing. They could really use a larger carder to process more wool at once, but had no luck searching for one.

‘Since my dad can make anything, he offered to build us a custom carding tool if we got him a metal sheet fitted with combing pins. Turns out, you can’t get one anywhere. We couldn’t source individual parts to build a bigger carder on our own, and so we struggle with the small one that we have. That’s why it takes so long; it’s a lengthy process in part due to the equipment’, explained Ivana.

Rough batches of wool are fine-combed until they transform into soft, airy clouds:

At that point, it’s finally time to felt. Several sheets of wool are stacked on a foam mat to make a rug, the number of sheets depending on the type of wool. Some are softer, some a bit rougher.

‘Our wool from Lika is more coarse, it takes more effort to work with. I also use wool from Pag island, that one’s softer. Interestingly, both are the Pramenka sheep breed, just originating from different areas.’

All Likamee rugs are unique, and Nada never makes the same design twice because it’s virtually impossible to repeat the same pattern. While some rugs retain the soft hues of natural sheep fleece, I’ve noticed a few eye-catching designs with accents of colour.

‘I started to dye the wool just to see how it would turn out. Since I’m working with eco wool, it only made sense to use eco-friendly dyes as well. I used coloured pencils at first and liked how it came out, then I started using natural purple dye. I’m planning to give avocado a try too… but mostly I just use natural wool. The experiments are more to ensure I have enough dyed wool at hand in case someone commissions a rug in a specific colour or pattern.’

Commissions are coming in indeed, and what started as a creative experiment and evolved into a hobby is now taking the shape of a business. For the last five years, it’s been all about learning. Now they’re working on branding and marketing, with Ivana managing the Likamee website and social media pages.

While they would both love for the project to become commercially viable and turn into a fully fledged family business, they primarily aim to build a strong design brand with a well-defined image: eco-friendly, high quality products.

In the meantime, they’re enjoying the creative process. Ivana said, ‘People love working with their hands, but aren’t fully aware of this until they actually start making something. It’s meditative, you get completely lost in it. It’s a different kind of focus than filling Excel sheets or preparing work presentations. We really enjoy it. It can be exhausting, but it’s so fulfilling.'

'The work is challenging, but so interesting', agreed Nada. 'There are times you get annoyed when something isn't turning out as you planned, but once you see your finished product, you know it’s all been worth it.'

We wish the best of luck to Likamee wool - head over to their website to browse the rug selection, and follow them on Instagram.

Unless otherwise noted, all images are courtesy of Likamee wool.

OPG Matulic: Hand Made Pasman Items Being Sought on Zagreb Market

December the 19th, 2021 - OPG Matulic from the island of Pasman just off the coast of Zadar began working only a decade ago, and they have attracted the attention of not only locals, but also the much larger Zagreb market.

As Poslovni Dnevnik/PD VL native tim writes, the Matulic family farm (OPG Matulic) from the island of Pasman was started ten years ago by Krsto and Ana Matulic. This family business includes growing olives, figs and chili peppers. They started with just one hundred seedlings, and today they have over 2000 seedlings of various chili peppers each and every year.

˝We're a small family farm, currently there are three of us, we have one hectare of land and we don't sell raw materials, only the finished products. We grow chili, figs, aloe vera, and we also have a lot of wild plants. My husband Krsto is in charge of the field and spices, and I'm in charge of cosmetics. This year has been very challenging and intense. Throughout the pandemic, we set up a production facility and devoted a little more time to online sales. There were also some other novelties. I launched three new products: Sea Tail - hand cream, Belle - face foam and the summer hit Lady sunshine. Krsto made some amazing chocolate with fig and maraschino acetate and olive oil,'' Ana Matulic said as she began OPG Matulic's story.

They started online sales a year and a half ago, and as they point out from OPG Matulic, they're very satisfied with the results and sales they've experienced so far, especially during the festive period. In their shop on Pasman, you can buy only their products, from hot sauces, flavoured salts, fig oils and acetates, to cosmetics based on olive oil and new sorts of chocolate. Back in the beginning, the majority of their products were bought by foreigners, and today there are more and more domestic customers who visit them and buy them as gifts for others and for themselves. The best-selling and most sought-after products are Pasman Libre fig aceto and Immortelle face cream.

The products from OPG Matulic have been awarded the Croatian Island Product label, three times they received the Sunflower Award of Croatian Rural Tourism, and they also received the Superior Taste Award for their Pasmanero in 2017 and for their Pasman libre fig aceto back in 2018, making them the very first small domestic producer with that award.

The International Taste Award in Italy back in 2020 went to the Pasman Libre for gold and silver went to their Pasmanero and wine vinegar. The latest award OPG Matulic took home was the Great Taste Award, and they received as many as three stars in England for Pasman Libre. Out of over 14,000 registered products, only 211 received three stars. They aren't aiming at having their products placed on the shelves of retail chains, as they say, they prefer small delicatessens and specialised shops, for example, Gligora has their products in its larger stores in Zagreb, Zadar and Kolan, and during the season they're present in a number of small shops on the coast and islands from Vis to Korcula, Hvar and Brac.

˝A lot of our restaurants in Pasman take our hot Pasmanero and Pasman Libre fig vinegar sauces. We're represented in catering and hospitality trades on Murter, Korcula, in Dubrovnik and in Zadar, and most recently in Zagreb in the new restaurant Al Dente in Bogoviceva street. In fact, someone often calls us from various restaurants and asks for an offer. However, since we don't sell our spices in larger packages than those available on the website, this will be a problem for most people in catering and hospitality. Some people, however, decide to take what we offer them and are generally satisfied. We don't have classic collaborations with hotels, but a few of them take our products for their souvenir shops, and some occasionally for gifts for their VIP guests. One of the longest collaborations we have is with Adriatic Sailing Charter, which takes our gift packages for guests on their luxury yachts,'' they stated from OPG Matulic.

When it comes to their spices, they produce most of the raw materials themselves, they buy figs from the local population right there on the island of Pasman, and when it comes to the production of cosmetics, they also cooperate with other family farms from which they purchase hydrolates, essential oils and beeswax. The production is located within their family house on the ground floor, and as Matulic explains, it is both an economic and residential space, and the production plant covers about 40 square metres in total.

For more, check out Made in Croatia.

Rijeka JGL Pharmaceutical Company Developing Rhinovirus Spray

December the 17th, 2021 - The well known Rijeka JGL pharmaceutical company has been busy developing an innovative cold spray which various substances targetting rhinovirus, the predominant cause of colds in humans, which haven't ever been used before.

As Poslovni Dnevnik/Marija Crnjak writes, the Rijeka JGL pharmaceutical company has teamed up in a partnership with the Centre for Proteomics of the Medical Faculty in Rijeka and with the scientific support of Biosens from Zagreb. This togetherness has resulted in the developing of an innovative ''Rino'' cold spray, with substances that have never been used in nasal sprays previously. The total value of the project stands at a massive 34.9 million kuna, and it is being co-financed by the European Regional Development Fund in the amount of 13.87 million kuna.

"This is a step forward for our company, since for the first time we're developing the product from the very beginning with substances that haven't been used in nasal sprays before, and which contribute to reducing the symptoms and progression of colds caused by rhinovirus, which is why we called it Rino spray. The project is also important because, as part of the strategy of ''smart specialisation'' of the Republic of Croatia, the thematic priority area "Health and Quality of Life" was chosen as one of the five key areas for the development of the Croatian economy.

With this project, we want to strengthen the position of our country, position ourselves as a European centre for the development and production of innovative health products through cooperation between production and research capacities of the private and public sector,'' said Masa Safundzic Kucuk, the director of research and development at the Rijeka JGL pharmaceutical company who is also the project manager. She also said that thanks to the help of the aforementioned fund, such projects don't put much pressure on the company's normal operations.

In-vitro product concept validation activities are underway to prove its safety and effectiveness, and experts from JGL and the Rijeka Medical Faculty are hoping for a roaring success in their product which will target the pesky rhinovirus, which is all too common of a bedfellow in winter.

"A team of scientists from the Centre for Proteomics of the Medical Faculty in Rijeka has been conducting scientific research in the field of immunology, virology, as well as research of new vector vaccines and immunotherapeutics, it's also participating in numerous national and international scientific projects with ambitious biotech and pharmaceutical companies like JGL. I'm convinced that the continuation of cooperation between the Faculty of Medicine and the Rijeka JGL pharmaceutical company on projects like this, as well as the expansion of cooperation in the direction of developing new immunotherapeutics will be of strategic interest to both partners.

Achieving this goal requires not only new investments through joint projects but also a vision of development based on the use of basic research results in creating new therapies or medical procedures,'' said Stipan Jonjic, head of the Department of Histology and Embryology and head of the Centre for Proteomics at the Medical Faculty of the University of Rijeka.

For more, check out our dedicated Made in Croatia section.

Croatian Idea Makes Damaging Fast Fashion More Sustainable

December the 15th, 2021 - A Croatian idea is turning old clothes which would likely end up being thrown away into sustainable fashion statements. The above idea was arrived to via a recently held UPSHIFT workshop in Zagreb.

As Poslovni Dnevnik/Lucija Spiljak writes, the UNICEF Office in Croatia and the Croatian Office for Creativity and Innovation (HUKI) recently held a three-day UPSHIFT workshop for young people from the City of Zagreb and the surrounding area of Zagreb County, dedicated to solving problems regarding environmental protection and sustainable development.

The interactive workshop attracted Croatian high school students who want to see problems in their local communities properly dealt with. 21 teams applied for this workshop, and ten of them aged 13 to 19 from the City of Zagreb and Zagreb County participated. Four teams won financial support of 7,500 kuna, as well as mentoring support for the realisation of their ideas.

One of them was team number 8, which wants to deal with the problem of fast fashion in the textile industry, also one of the biggest challenges of today. The team consists of Luka Marusic Smajic, Jan Filipovic, Gabriela Dedic, Lucija Bekavac and Maria Paula Klekovic from the School of Fashion and Design Zagreb. Their fashion-oriented Croatian idea was an impressive one.

"Our goal isn't to solve the problem that we're all facing on a global basis, but to make people around us aware of it. We'll try to solve this problem by redesigning old clothes that are no longer desirable. We'll implement this solution by holding a fashion show of our redesigned collection and posting educational videos on social media, in which we'll teach people how they can redesign their old clothes themselves. There will be advice, examples, instructions and so on,'' the team members explained.

They stated that they were encouraged to attend the workshop by their professors and professional associates who educated them about the challenges of fast fashion and encouraged them to solve problems. The aforementioned financial support of 7,500 kuna will be used for advertising, the necessary materials for redesign, as well as for the collection and the subsequent fashion show itself.

Their main focus is on young people who, according to the team members, are often unaware of the problem of accumulating old fabrics, as well as the fact that they themselves contribute to it on a daily basis.

"Few of our peers are thinking about this problem and it isn't covered enough in the media. In addition, the fashion industry is very fast-paced and also doesn't contribute to solving the problem whatsoever. Fortunately, our school talks a lot about fast fashion and its impact on the environment, so we're more aware of this. It's important to choose quality over quantity and to encourage manufacturers to offer clothes of natural composition(s). Also, people should put together their own styles, ignore passing trends, and occasionally be creative, not just pliable,'' concluded the team from the Zagreb School of Fashion and Design.

Other teams from the UPSHIFT workshop in their communities will deal with solving the problem of air pollution in Zagreb, ''dehumanised'' classrooms in Croatian schools and launching the mission ZaZeleniZagreb (For a Green Zagreb).

For more, check out Made in Croatia.

Croatian Student Team Make Vegan Cake from Agricultural Waste

December the 14th, 2021 - A Croatian student team has put agricultural waste to good use and created a vegan cake from it. The Not Your Ordinary Cookie team has created the ''Zdravko'' vegan delight, and it's likely to win many over.

As Poslovni Dnevnik/Lucija Spiljak writes, Dora Senjug, Virna Klara Tus and Dora Vlahovic from the Faculty of Food Technology, Fran Duspara from the Faculty of Pharmacy and Biochemistry and Hrvoje Magas from the Design of Visual Communications in Split make up the Not Your Ordinary Cookie team whi have come up with ''Zdravko''.

To speak more specifically, Zdravko is made with the addition of potato peel powder and industrial hemp seeds, and then stuffed with dried figs and carob. It is completely of plant origin, without any added sugar, and is characterised by a high content of dietary fiber and minerals desirable for a balanced diet.

"Our goal was to support Croatian farmers and family farms, so we got all the food we could get from them. We made sure that potential suppliers have a certificate of organic farming, ie they do not use pesticides,'' this Croatian student team explained.

They say they have seen the potential in the use of agrowaste, or by-products of processing various crops that are often thrown away, despite the high content of bioactive components such as vitamins, fiber minerals and antioxidants.

"We agreed that potato peelings, but also industrial hemp cake, are exactly what we want to work with because, in addition to being unjustifiably rejected, they're quality foods rich in fiber and minerals that have a positive effect on human health. Hemp bread has already started appearing on store shelves, but potato peelings also have undiscovered potential. Sustainability is an imperative of the modern food industry that we must turn to as soon as possible.

Apart from the fact that the by-products of the production of some crops can be put into other functional food products, as well as their individual components, they can also be used in other industries. For example, the peel of characteristically coloured fruits and vegetables is often discarded, and the pigments extracted from them have the potential to be used in the textile industry. Before we turn to synthetic substances, we might be surprised if we properly study the natural alternatives that we actually handle every day and often end up, unfortunately - in the bin,'' the Croatian student team emphasised.

Just how impressive and innovative their products are has been well and truly confirmed by them winning first place in the competition of student teams called Ecotrophelia Croatia 2021 which was held back in June at the Faculty of Food Technology and Biotechnology in Zagreb, which aims to encourage student creativity, innovation, interdisciplinarity and the promotion of food products on the demanding and fast-paced European market.

The Croatian student team is proud of them having won first place, because this is a kind of business incubator for eco-innovative food products, which included designing and preparing the product, thoroughly processing and explaining all of the nutritional qualities, devising the entire technical-technological plan (balance sheets, the design of the plant, and all associated devices), and developing a full and functional financial and marketing plan.

The European version was supposed to take place in Cologne in October, but due to the coronavirus pandemic, the organisers opted for an online form of competition this year as well. They won the 4th place back at that time, which is allegedly the highest place ever won by any Croatian team. In addition, they consider it a great success because they financed the project from their own, student pockets.

"We'd like to thank all those who helped up in the realisation of the Zdravko cake from the bottom of our hearts. It would be really nice to see our product on store shelves. Precisely because of the product itself and the affordability of the price we'd offer, we believe that customers would be quick to recognise the quality of Zdravko. We're researching options, there are many factors to consider - from the establishment of a company, all of the technological requirements and the like. We certainly hope that someone will see our potential, as well as the potential of our product, and that we'll manage to reach a common goal through cooperation and mentoring. Until then, of course, we'll do our best to be noticed. We hope that our example will motivate others to try to realise their ideas and projects, because the experience gained teaches you so much and no one can take it away from you. Who knows what kind of doors can be opened on the way,'' concluded this Croatian student team.

For more, check out Made in Croatia.

Mate Rimac: We Want to Develop Profitable Company, Create Something New

December the 8th, 2021 - Mate Rimac has done more to show the world that it is very much possible to succeed in Croatian entrepreneurship than anyone else. Perhaps Ivan Mrvos comes a close second, but for the automotive world which would never have given the country a second look, what he has done is truly historic.

As Poslovni Dnevnik/Zoran Vitas writes, after a joint venture with Bugatti and the creation of the new Rimac Group, Mate Rimac and his dedicated team have a much harder job on their hands in Sveta Nedelja near Zagreb than they did before. When the German Manager Magazine announced that it was considering going public with an expected estimated value of five billion euros, a lot was written about that possibility.

It was even mentioned by Lutz Meschke, Deputy Chairman of the Executive Board and a member of the Finance and IT Management Board at Porsche AG. One day an IPO would make sense.

''Mate Rimac must first implement his company's operational plan, but he can count on our support,'' said the leader of the cult German company.

Mate Rimac explained back in November for Automobilwoche what the implementation of such an operational plan means. He was short and clear - profitability. That is, significantly improved profitability.

“At Bugatti Rimac, we're focused on profitability. We don't want to rush, but instead we want to give ourselves time to prepare everything thoroughly. This could be done in 5-10 years,'' said Mate Rimac about the brand with which, realistically, Volkswagen had some trouble.

"It would be easiest to take the Nevera, redesign it and call it Bugatti. But that is absolutely not what we're going to do,'' Rimac repeated. When Bugatti's last Chiron leaves the factory in Molsheim, it will be Bugatti's turn,'' which, as he said during Ursula von der Leyen's visit, makes the most sense.

“Porsche runs on carbon-neutral or even positive fuel because of the way it is produced. In the medium term, it would make the most sense for Bugatti to be a hybrid. It is true that Porsche wanted us to go to electricity immediately, but we said that we'd like to work with petrol engines for some time to come, with a new generator. But that's where I'll stop,'' said the head of Bugatti Rimac, stating that they have been working on the development of the new Bugatti in Croatia for a year now.

"We want to make a profitable company, but we won't recycle anything. We will not redesign the Chiron and thus make a new model, or just hybridise it, we're developing an entirely new product. And that product will still have an internal combustion engine. We're also looking at it in the long run knowing how Bugatti has known diversity throughout history that can be used not only to make hypercars. It's an opportunity to produce different and exciting cars that will be both electric and electrified. We'll have fully electric Bugattis in a decade,'' Mate Rimac said in conversation with the British Top Gear.

For more, check out Made in Croatia.